Greenyard Fresh France

Quality Manager

Quality has always been at the heart of the Greenyard Fresh France policy, in order to allow it to ensure its growth within an ever-stricter statutory setting, for an ever more demanding clientele.

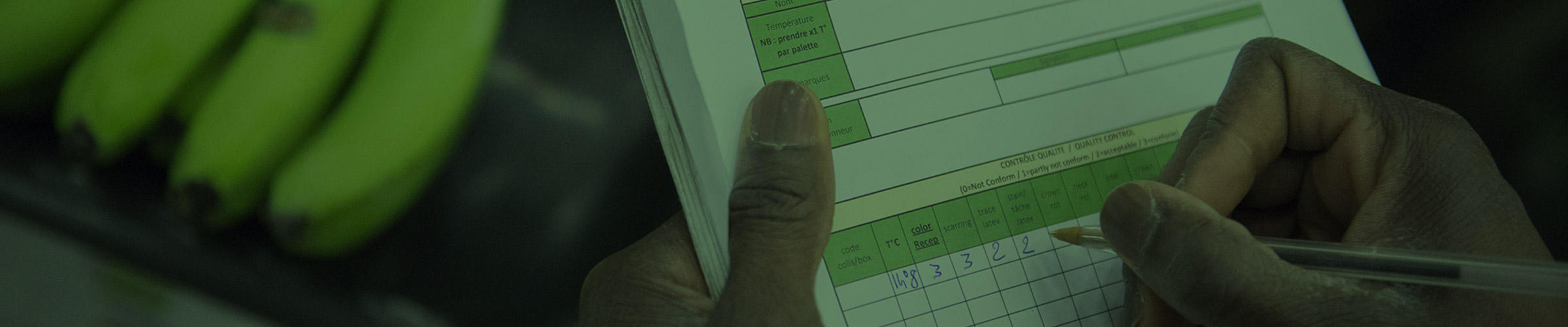

Operational Quality

This means monitoring products from reception of goods, during their storage and preparation and up to the point they are shipped. The Quality department therefore carries out approvals (acceptance checks) on incoming products. This control is carried out with regard to quality criteria established in the supplier specifications. This initial control allows for identifying the goods to be prepared as a priority, for providing information to the product manager and also to the supplier. Once the goods are stored, we carry out a quality control of the products throughout their storage phase. During order preparation, we direct the preparation agents to the batches to be used and we check the preparation in order to guarantee compliance with customer requirements in relation to their specifications.

All these control processes are materialized by the signature of the FeL Partenariat agreement. The aim of this FeL Partenariat agreement, in addition to compliance with legal obligations, is to satisfy customer expectations on a food safety level (qualified staff capable of applying the hygiene, health and safety and traceability procedures). This operational quality, complying with European statutory hygiene requirements (Regulation (EC) No. 178/2002) has been strengthened by the implementation of IFS (International Food Standard) Food & Broker baselines in 2014.

The Quality System

This corresponds to ISO 9001V2015 certification, the standard to which Greenyard Fresh France has been certified since 2001. This certification incurs several principles, including: customer orientation (satisfaction and consideration of implicit and explicit requirements), management and staff involvement, mutually beneficial relationships with suppliers, and the principle of continuous improvement.

The quality system, which follows ISO 9001, is first and foremost a management tool that improves the collective organization and overall operation of the company, in the aim of sustainably satisfying our customers’ requirements and expectations.

Greenyard Sustainability project

The Quality department is also responsible for developing lines of improvement for subjects such as productivity, safety and the environment, as well as corporate social responsibility. As a result, Greenyard Fresh France plays a role in the “Greenyard Sustainability project “, the aim of which is to reduce our environmental impact from distribution and logistics operations, improve social standards in all aspects of our organisation, and to pursue sustainable supply methods.

We also hold BIO (organic) by Ecocert and Fair Trade certifications.

Likewise, all the group’s producers are GLOBALGAP certified and we encourage our suppliers from outside the group to follow the same approach.

Lastly, the group’s conditioning and storage stations have implemented an HACCP system.

After having initiated a risk assessment procedure (HACCP), Greenyard Fresh France naturally turned to ISO 9001 (V2015) certification, which it obtained in 2001

Our controls

A meticulous Quality policy involves strict controls at all levels